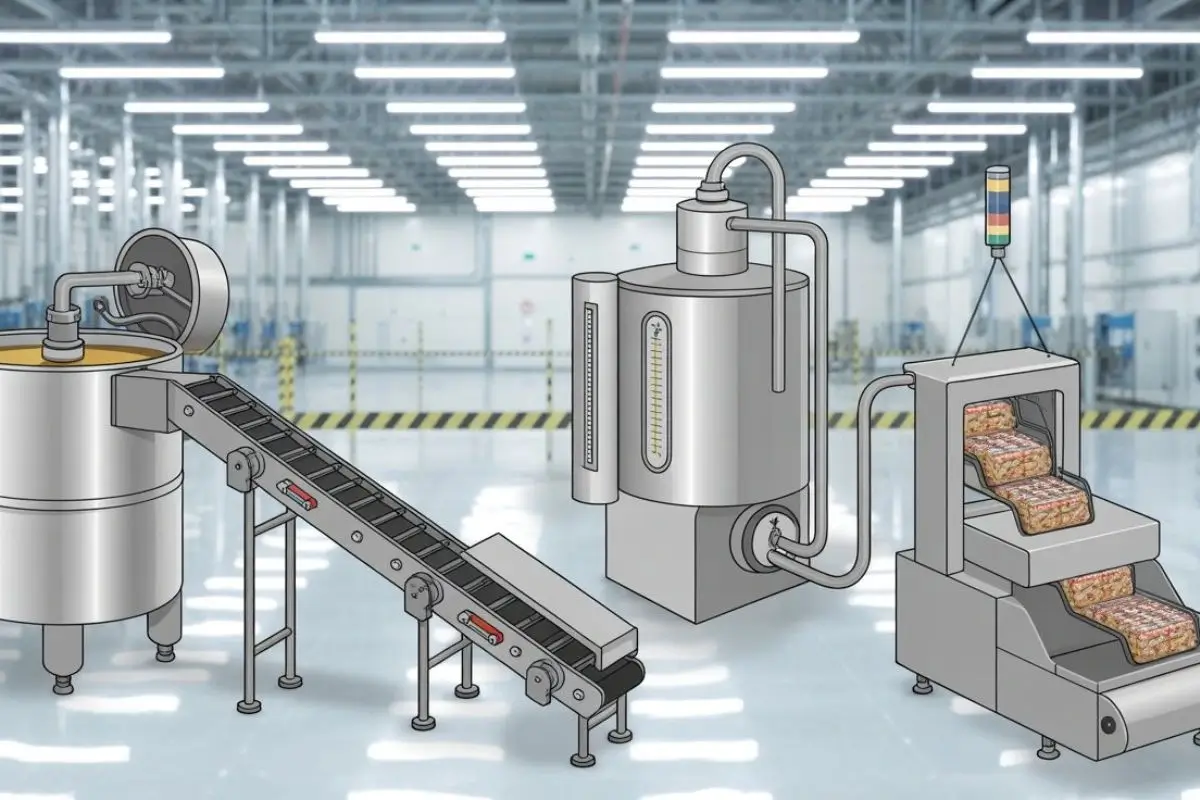

Food Processing Equipment consists of the machines and tools used to convert raw ingredients into finished food products. From mixing to grinding and cooking, the different types of food processing equipment handle the foods safely, consistently and quickly.

Whether you want to make sauces, snacks or frozen meals, these machines play a vital role in keeping your food quality high. With the right types of equipment in your industry, you can boost efficiency, reduce waste and meet the safety standards. Let us read this guide and learn the different types of Food Processing Equipment with their uses.

Types and Uses of Food Processing Equipment

Food Processing Equipment is widely used in large-scale food production facilities. It handles the different stages of food preparation efficiently and ensures high-quality output and compliance with hygiene standards. Here are the types of food processing equipment with uses.

1. Cleaning and Washing Equipment

Hygiene is a main focus in food processing, which makes cleaning and washing equipment crucial. This machinery cleans dirt, debris, and contaminants from raw ingredients. The machines like

o Vegetable Washers: Used for leafy greens, carrots, and potatoes.

o Fruit Washer Machine: Equipped with brushes and spray nozzles to clean fruits like apples, citrus, and berries.

o Ultrasonic Cleaners: Used for delicate products, providing a gentle yet thorough cleaning process.

2. Mixing Equipment

Mixers are essential in both small and large food operations. They combine ingredients evenly, whether you’re working with dough, meat blends, sauces, or seasonings. Modern food mixing machines feature programmable mixing cycles and hygienic designs, allowing control over product texture and consistency.

3. Grinding and Cutting Machines

Grinders and cutters are vital for preparing meats, vegetables, and other ingredients to specific sizes. For example, an industrial meat grinder streamlines bulk meat preparation, ensuring uniform sizes for sausages, burgers, or deli items. Many facilities also use bowl cutters, food emulsifiers, and flaker equipment to achieve the desired ingredient size and structure.

4. Conveyors and Handling Systems

Conveyor machines and handling systems are used to move products through the processing line. Automated conveyors reduce manual handling, lower contamination risks, and improve line efficiency. Loader and transfer equipment, like loader machines, connect processing steps, optimizing flow and reducing labor needs.

5. Tumbling, Injecting, and Marinating

To spread seasonings or brines and improve product texture, processors use machines like vacuum tumblers and brine injectors. These devices infuse flavors or solutions evenly and can greatly shorten marination times, all while ensuring food safety by minimizing manual handling.

6. Cooling and Freezing Equipment

After food is processed or cooked, it often needs cooling or freezing to keep its quality and extend shelf life. Foods can spoil quickly if not stored correctly. The types of food processing equipment, like chillers, freezers, and blast chillers, are crucial in this phase. They rapidly lower temperatures, helping to prevent microbial growth and ensure food safety.

7. Cooking, Smoking, and Baking Systems

Cooking, smoking and baking systems are specialized equipment in the food processing industry that preserve the food quality efficiently. In the bakery sector, ovens and proofers are vital for mass-producing bread, pastries, and other baked goods.

8. Packaging Equipment

Automated packaging systems ensure that products are sealed, labeled, and ready for distribution. These types of food processing systems may include vacuum packaging, sealing, labeling, and coding, all important for compliance and customer satisfaction.

9. Pasteurizers

This type of Food Processing Machinery heats liquids like milk, juices, and sauces to a specific temperature to kill harmful bacteria while maintaining product quality. Pasteurization is necessary for food safety and extending shelf life.

10. Dryers and Dehydrators

Dehydration removes moisture from food, extending its shelf life without refrigeration. This is especially useful for fruits, vegetables, and meat snacks.

How Envitro Technomech Helps You Choose the Right Equipment

Choosing from the different types of food processing equipment is tough. At Envitro Technomech, their team works with you from the earliest consultation to the final installation. They understand your products, requirements, and facility constraints, then recommend equipment or complete lines tailored to your needs, whether you want a standalone food grinder or a custom multi-stage processing line.

Their support doesn’t stop with installation. They support every piece of equipment we provide, and offer responsive maintenance to keep you running smoothly and minimize downtime.

Conclusion

Food processing equipment plays a vital role to transform the food sector. It plays a crucial role in transforming raw ingredients into safe, nutritious, and appealing products. Each type of equipment has a specific function, from preparation and cooking to packaging and quality control.

It ensures food products are produced efficiently, safely, and with consistent quality. As technology continues to develop, food processing equipment will become more sophisticated, enhancing how we produce and consume food worldwide.

FAQs

Q1. What Are the Types of Food Processing Equipment?

Ans: The different types of food processing equipment are categorized into mechanical processing tools, preparation tools, thermal processing equipment, preservation, and packaging equipment. The types of machines in these categories are grinders, mixers, slicers, sterilizers, dryers, and vacuum sealers.

Q2. What is the Use of Food Preparation Equipment?

Ans: The main uses of food preparation equipment are cleaning, cutting, mixing, blending, freezing, cooling and maintaining the quality of food products. These machines keep uniformity and reduce manual labor. It makes these machines suitable for large-scale food production faster.

Q3. How Does Thermal Processing Equipment Work in a Food Production Facility?

Ans: The thermal Food Processing Machinery, like steamers, ovens, pasteurizers, and sterilizers, are used to heat the food, destroy bacteria and extend shelf life. It also ensures food safety and retains the nutritional value, texture and color of food items.

Q4. What Are the Uses of Mechanical Food Processing Machines?

Ans: The mechanical food processing machines like slicers, grinders, mixers and extruders are used to change the shape, size and texture of food items. It is used in dough preparation, meat processing and daily production to achieve the product quality and enhance efficiency.

Q5. Why is Packaging Equipment Used in the Food Industry?

Ans: The food packing equipment, like vacuum sealers, filling machines, and labeling systems, is used to seal, label and wrap the food products and maintain the freshness. These machines also enhance shelf life and adhere to food safety standards.

Read Also: Different Types of Water Treatment Plants for Industrial Use