Rotary retort and vertical autoclave machines are widely used in the Food processing industries. Such industries often rely on sterilization technologies and ensure that the packaged products are long-lasting, safe and free from contamination.

Choosing the right machine for a Food Processing Plant is tough, and it affects the product quality, operational costs and production efficiency. This blog serves as a comparison guide on Rotary Retort vs Vertical Autoclave and helps you to choose the right machines for your industry.

What is a Rotary Retort?

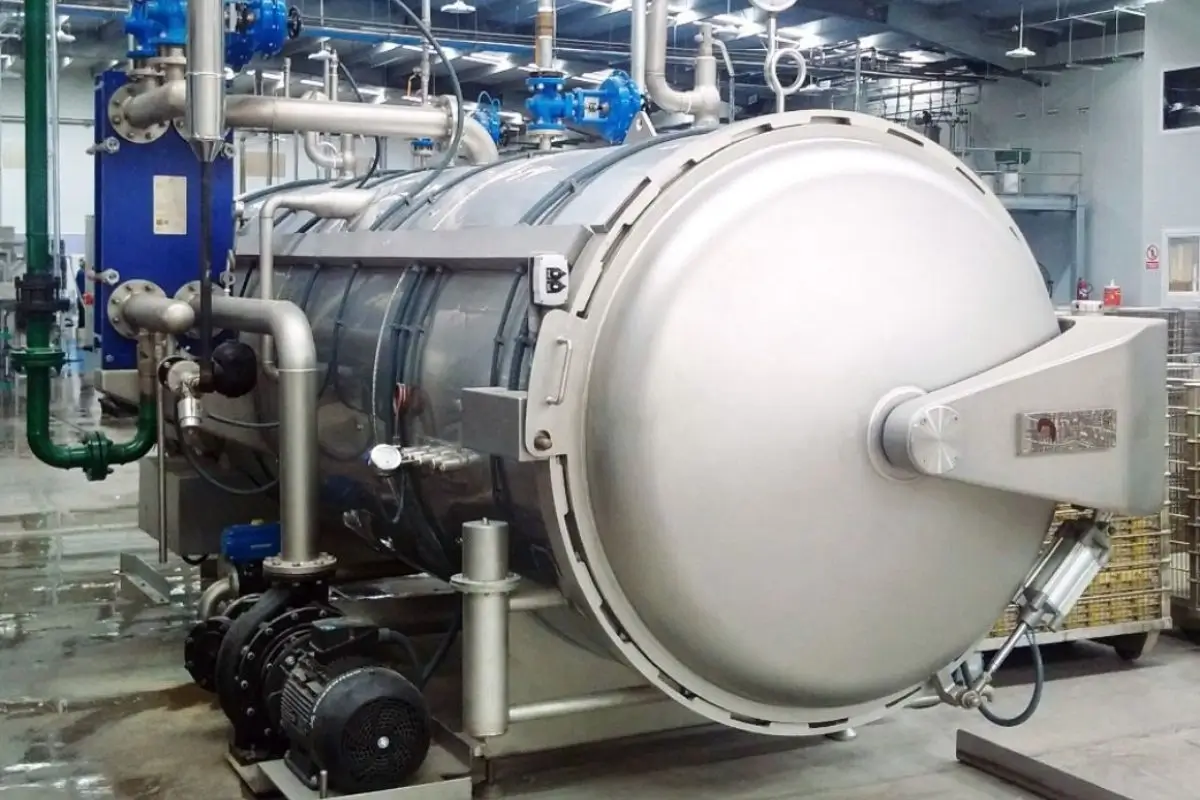

The rotary retort is a pressurized vessel that uses steam and high temperatures to sterilize packaged foods. It ensures microbial safety and extended shelf life. These machines are commonly used for canning and ready-to-eat meal production.

What is a Vertical Autoclave?

The vertical autoclave is a specialized autoclave machine used for food industry applications. It works under similar pressure and heat principles and kills pathogens in sealed containers.

Key Features of Rotary Retort Machines

The key features of rotary retort machines are given below, including freshness, quality preservation, nutrient retention, cost effectiveness, etc.

1. Preserve Freshness

Retort machines work to keep their products longer by killing harmful microorganisms, which reduces food waste. It also extends the shelf life of food products.

2. Nutrient Retention

Some preservation methods lead to a loss of essential vitamins and minerals. So here the Rotary Retort Machine Manufacturer helps and retains the same nutritional values of your food products.

3. Uniform Quality Control

The retort machine standardizes treatment for every product in a batch, ensuring a high-quality outcome, which contributes to brand reputation.

4. Flexible Packaging Types

Retort machines accommodate various packaging types to meet consumer demands. They can process everything from cans and jars to flexible pouches.

5. Cost Effectiveness

Another feature of Retort machines is that they are cost-effective machines. It reduces the need for manual labor and reduces product recalls because of spoilage.

6. Safety Guidelines

The food industry has strict guidelines regarding food safety. The retort machine is a proven food safety system and has been successfully used in producing canned foods.

Key Features of Vertical Autoclave Machines

Here are the features of vertical autoclave machines

- The compact design of autoclave machines saves space and fits well in facilities with limited room.

- It applies steam pressure, destroys the viruses, spores, bacteria and achieves high sterilization efficiency.

- To operate the autoclave machines, minimal effort is required because of their user-friendly control system.

- These machines are made with high-quality SS material and give a long-lasting structure.

- This equipment offers versatile sterilization capabilities for different materials such as surgical instruments, glassware, and textiles.

Key Applications: Rotary Retort vs Vertical Autoclave

Here we tell you the uses of the retort and vertical autoclave machines

Uses of the Retort Machine

- Commercial canning (vegetables, soups, meats).

- Ready-to-eat meals (retort pouches for camping/hiking food).

- Pet food sterilization.

Uses of vertical Autoclave

- Laboratory food testing (sterilizing equipment).

- Small-batch artisanal food preservation (e.g., jams, sauces).

- Pre-packaged organic products require gentle sterilization.

Detailed Comparison: Rotary Retort vs Vertical Autoclave

Here is the quick comparison guide on the Rotary Retort vs Vertical Autoclave machines, which helps you to choose the right Food Processing Machinery for your industrial requirements

| Feature | Rotary Retort | Vertical Autoclave |

| Operation | Rotation of packages is continuous | Stationary packages |

| Heat Distribution | Uniform Heat Distribution reduces cold spots | Less uniform Distribution, possible cold spots |

| Processing Time | Shorter cycles | Longer cycles |

| Production Capacity | High, ideal for large-scale production | Low to medium, ideal for small-scale production |

| Product Quality | Better preservation of taste, color, and nutrients | Higher risk of overcooking in stationary zones |

| Initial Investment | High | Moderate |

| Maintenance | More complex because of the moving parts | Easy and simple maintenance |

| Suitability | Large plants with high output | Small to medium plants or startups |

| Versatility | Handles jars, cans, pouches, trays | Handles jars, cans, and bottles |

| Automation | Highly automated with PLC control | Manual operation or Semi-automated |

Making the Right Choice for Industry Requirements

The right machine choice between the Rotary Retort and Vertical Autoclave machines depends on your industry needs. Here’s how we help you make the right choice.

- If your main focus is sterilizing medical instruments, lab equipment, or biological waste: You need the validated, pure-steam process of an autoclave.

- If your focus is producing shelf-stable packaged foods like cans, pouches, or jars: You need the controlled overpressure of a retort for food safety and package integrity.

- If your focus is research using high-pressure steam on non-sealed materials: An autoclave is probably the most effective and economical choice.

Selecting the right machine ensures not only your process’s success but also the safety and integrity of your final product.

Choose Envitro Technomech to Buy Sterilization Solutions

Envitro Technomech is the trusted Rotary Retort Machine Manufacturer to buy high-quality machines. It meets your industrial requirements for modern food processing plants. Their top-notch machines ensure precise sterilization, superior product quality, and optimal operational efficiency.

They also provide you with customized machines and automated ready systems and help the food processors to achieve consistency, safety, and productivity in every batch. Rely on Envitro Technomech to enhance your plant’s performance with innovative, dependable, and cost-effective sterilization technology.

Conclusion

Both rotary retorts and vertical autoclave machines have unique benefits in the food processing industry. Your decision between Rotary Retort vs Vertical Autoclave depends on factors like production volume, product type, budget, and long-term operational goals.

Rotary Retorts are perfect for large-scale, high-volume operations focused on product quality, consistency, and automation. Vertical Autoclaves are perfect for small or medium-scale operations needing a cost-effective, simple, and flexible sterilization solution.

Before buying the right machine, you should understand the plant’s capacity, production goals, and product specifications. It helps you to invest in the right technology and meet the food safety and quality standards. It also helps to increase operational efficiency and profitability.

FAQs

Q1. Which is the Right Machine for a Food Processing Plant, a Rotary Retort or a Vertical Autoclave?

Ans: The choice of the right machine for a food processing plant depends on your production facility, budget and industry requirements. The Rotary retort is suitable for large-scale operations that require fast processing, sterilization and high-quality output. On the other hand, vertical autoclave machines are suitable for small to medium-scale plants that have lower batch volume requirements.

Q2. Can a Vertical Autoclave Sterilize High-acid Foods?

Ans: Yes, a vertical autoclave can easily sterilize the high-acid foods.

Q3. What Maintenance Does Rotary Retort Machines Require?

Ans: The Rotary retort machines need regular maintenance because of automation systems and moving parts. Skilled technicians are required for your machine to maintain it properly and ensure optimal performance.

Q4. Do Rotary Retorts Machines Energy-efficient?

Ans: Yes, the rotary retorts are energy-efficient machines and save energy in the long run. Make sure to buy the efficient equipment from a trusted Rotary Retort Machine Manufacturer.

Q5. Can Vertical Autoclaves Be Automated Machines?

Ans: Yes, the vertical autoclave is an automated machine, but it offers semi-automation with temperature controllers and timers.

Read Also: Top Benefits of Automation in Modern Dairy Processing Plants